Why does a sewing machine stop stitching when it worked fine yesterday? The issue often lies in small, easy-to-fix details. These details can affect how the machine is set up and cared for.

People often think it's the motor's fault. But, it's usually something simpler like wrong threading or a bent needle. Sewing machine tension problems can also mess up the stitches. If the needle doesn't move and you see loops or breaks, it might be the threading or bobbin placement.

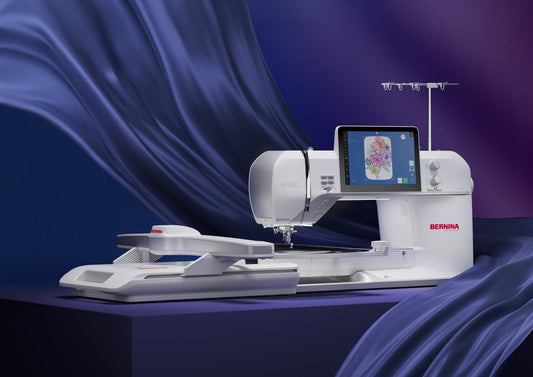

Even top brands like Singer, Brother, Janome, or Bernina can have issues. This can happen if there's too much lint or the presser foot pressure is off.

Choosing the right thread is also important. Bad thread can cause the machine to snag and not sew straight. A dull or wrong-size needle on certain fabrics can also cause problems. By checking these things carefully, you can get your machine sewing smoothly again.

Key Takeaways

-

Most “no stitch” moments trace to threading errors or sewing machine tension problems, not motor failure.

-

A bent, dull, or wrong-size needle causes skipped stitches and the sewing machine needle not moving smoothly.

-

Matched, quality threads reduce breaks and prevent a sewing machine not sewing straight.

-

Correct bobbin winding and direction are vital for reliable stitch formation.

-

Clean feed dogs, proper presser foot pressure, and the right plate keep fabric moving.

-

If simple fixes fail, internal timing or service may be needed from a qualified repair shop.

Why would a sewing machine not stitch?

A common reason a sewing machine won't stitch is mis-threading. If the top thread doesn't follow the right path, fabric puckers or the stitch doesn't form. The same issue happens with the bobbin if it unwinds the wrong way or is wound too loosely, leaving gaps or loops.

The type of needle used can also affect stitching. A bent or dull needle prevents the loop from meeting the bobbin. If the needle is too short, too long, or not seated properly, the hook can't grab the thread. This causes the bobbin thread to not catch on every pass.

Tension settings are key to maintaining stitch balance. If the top thread is too tight or too loose, the knot will shift to the wrong side. Debris between tension discs can also affect draw rates, leading to uneven stitches. Balanced tension ensures the interlock stays centered.

Bobbin parts can wear out or be poorly wound, causing issues. A chipped bobbin, a jam in the case, or using different thread weights can lead to erratic pulls. Clean, even winds with quality thread from brands like Gütermann help stabilize flow.

Feed and presser foot conditions also impact stitching. If the presser foot is up or the pressure is set too light, fabric slips, and timing feels off. Lowered or covered feed dogs stop fabric movement, which may look like a sewing machine bobbin thread not catching when the real issue is feed control.

Mode and handling are important too. If bobbin-winding mode is engaged, the needle won't move even though the motor runs. Forcing thick layers can bend the needle, shift timing, and bring back the question: why would a sewing machine not stitch? Smooth guidance—no pulling—keeps parts aligned.

Thread quality and matching also shape results. Mixing coarse top thread with a fine bobbin thread leads to snags and loops. Consistent type and weight reduce drag, preventing a sewing machine not catching thread and helping the stitch lock remain steady across seams.

Troubleshooting sewing machine stitching issues: not catching thread, skipping stitches, and fabric not feeding

Start with the basics when you're having trouble with your sewing machine. If it's not catching thread, try re-threading with the presser foot up. This opens the tension discs. Make sure the needle is straight, fully seated, and the right size for your fabric and thread.

Check that the bobbin is in the right direction and is wound smoothly. Also, clean out any lint from the case spring. Balance is key. Many issues are solved when the dial is near the midrange.

-

Sewing machine skipping stitches often means a dull or wrong needle. Use a ballpoint for knits and a sharp or heavy-duty option for denim or leather.

-

Re-thread both paths so the top thread can meet the bobbin loop. Confirm the take-up lever is engaged.

-

Check presser foot choice and pressure. A wide throat plate hole, light pressure, or a zipper foot set too far from the needle can cause skips.

-

If skips continue with correct setup, the hook timing may be out and require service.

For a sewing machine not feeding fabric, check the mechanics and setup. Raise the feed dogs and remove any darning or embroidery cover. Clean lint from the teeth and replace worn feed dogs that feel smooth to the touch.

-

Set presser foot pressure for the fabric weight, and lower the foot before sewing so the dogs can pull evenly.

-

Review stitch length and regulator settings. A disengaged feed or misaligned throat plate will stall movement.

-

Support the project instead of pulling. On knits, slick satins, or heavy quilts, a walking foot from brands like Janome, Brother, Singer, or Bernette helps sync top and bottom layers.

To reduce jams and bird’s nests, thread with the foot up and start with the take-up lever at the top. Keep bobbin tension consistent. Address thread breaks by matching thread weights, easing top tension when needed, and replacing any presser foot or needle plate that shows burrs.

To prevent puckering, align stitch length and tension with the fabric and match thread size across the spool and bobbin. Clean and oil per the manual, brushing lint from the bobbin area, feed dogs, and tension path. Avoid compressed air that can drive debris deeper, and schedule service if the machine runs noisy or tight after long storage.

Conclusion

Most sewing machine problems are simple. The main reasons include correct threading, a fresh needle, and balanced tension. Using the right thread and keeping the machine clean also helps.

When a sewing machine won't catch thread, try re-threading with the presser foot up. Check the bobbin's orientation and winding. Swapping worn bobbins can also help.

If stitches are skipping, use the right needle for your fabric. Make sure threading is correct and presser pressure is set right. Also, check the plate and foot choice.

For fabric feed issues, raise and clean the feed dogs. Adjust the presser pressure and check the stitch regulator and throat plate position.

Good technique is key to avoiding stitch problems. Don't pull the fabric and support heavy projects. Place pins carefully to keep the needle path clear.

A walking foot can help with knits, vinyl, and quilts. It reduces stretch and misalignment, preventing skipped stitches.

If problems persist, like unusual noises or repeated misses, stop and get professional help. Fixing these issues early prevents damage. It keeps your sewing machine working well, from simple hems to complex quilts.

Visit our website today for top-quality sewing machines, notions, thread, and more!